Autopackers

Choosing the Right Autopacker for Your Nail Production Needs

Autopackers are essential tools for optimizing the final packaging process in industrial nail manufacturing. These automated systems streamline the packing of wire nails, ensuring efficiency, cost reduction, and enhanced product quality. Depending on your specific production requirements, choosing the right autopacker can greatly influence the overall performance of your production line. Whether you are handling bulk nails or collated nails using wire, plastic strips, or paper tape, there is a suitable autopacker for every need. Comparing systems such as Basic Autopackers, CAP, and WP-25 can help manufacturers identify the most efficient solution for their unique operations.

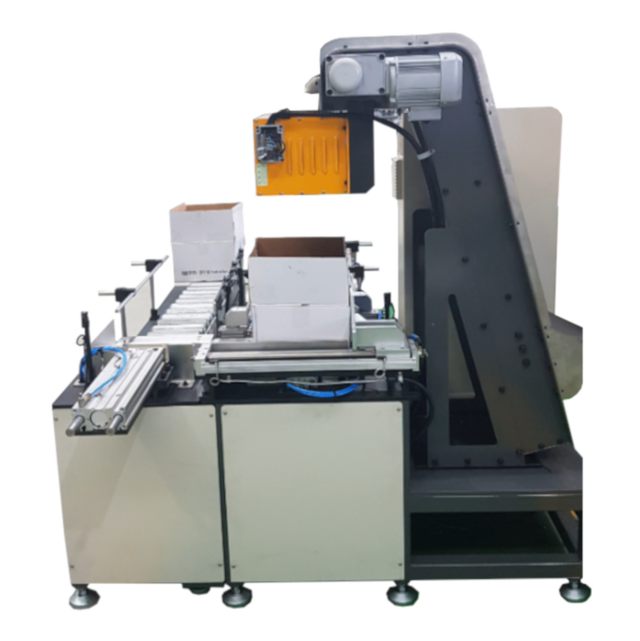

Autopacker: The Foundation of Automated Nail Packaging

An autopacker is a specialized system positioned at the end of a nail production line, designed to automatically pack nail rolls into cartons. By automating this process, it eliminates the need for manual labor, increases productivity, and reduces costs. This reliable machinery ensures that nails are packed quickly and securely, ready for immediate distribution. Its universal application makes it a cornerstone of modern nail manufacturing operations.

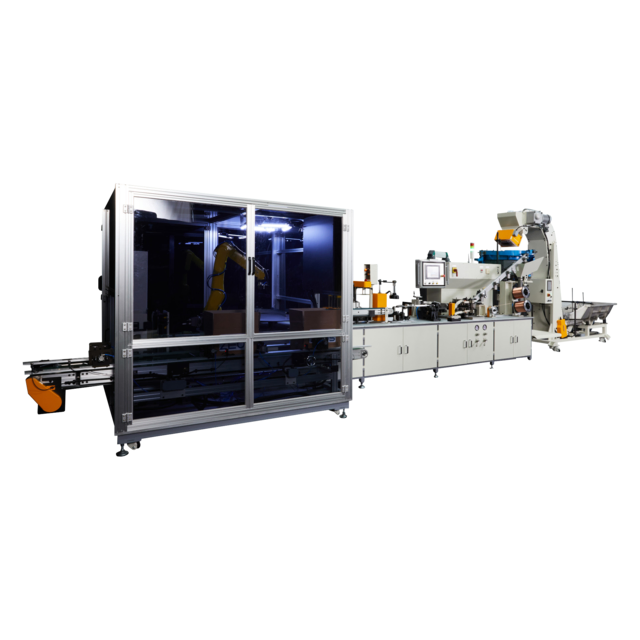

Autopacker CAP: Perfect for Wire-Collated Nails

The CAP autopacker is designed for nails collated with a wire welding collator. This system automates the packaging of nails that are aligned and connected using thin welded wire. The CAP system integrates advanced AI-powered technology to monitor the quality of nail coils as they arrive from the collator. Cameras inspect each coil, ensuring it is not unwrapped, deformed, or missing a rubber band. Additionally, the system identifies rust or other deformities on the nails. If a defect is detected, the AI directs a robotic arm to remove the faulty coil and set it aside for disposal. Furthermore, a second AI-powered camera oversees the packaging process within the carton. It determines when to insert spacers between nail coils and ensures the carton is filled correctly and securely. This intelligent automation not only boosts efficiency but also guarantees that only high-quality products reach the end-user.

Autopacker WP-25: Reliable Bulk Nail Packaging

The WP-25 autopacker is tailored for bulk nail packaging. It is especially suited for nails within specific diameter and length ranges, offering an efficient solution for high-volume nail production lines. Known for its precision and reliability, the WP-25 can handle large quantities of nails with ease, ensuring they are securely packed for transportation and use. For manufacturers aiming for cost-effective and high-capacity packaging, this system is an excellent choice.