Auxiliary Equipment

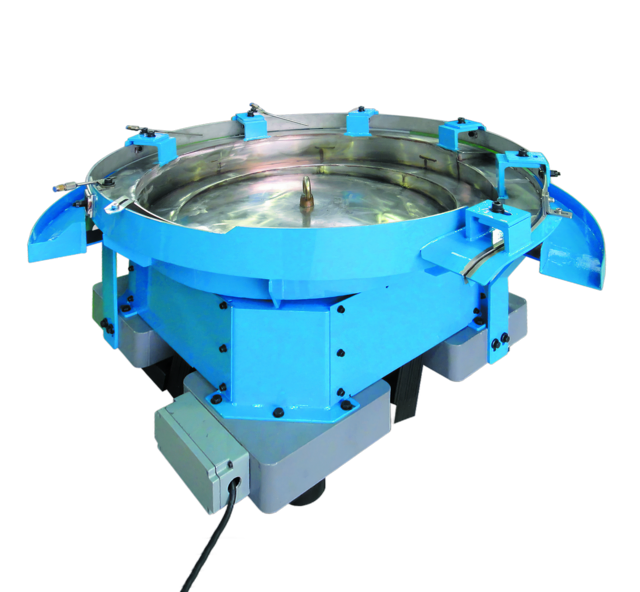

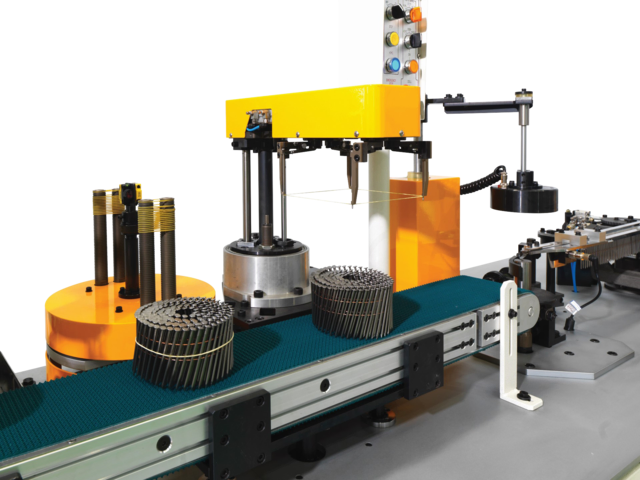

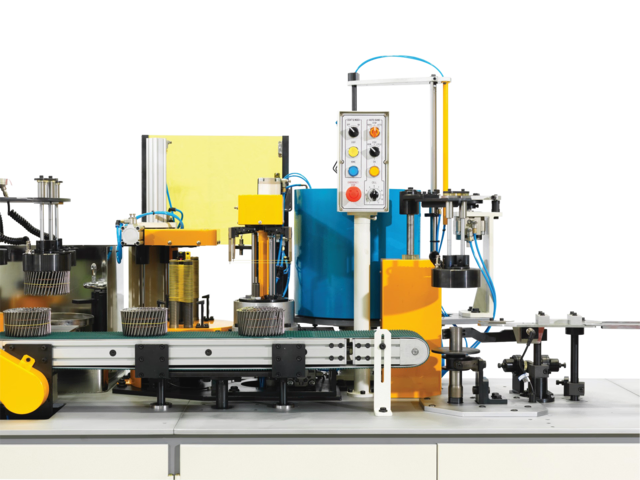

Nail bowl feeder

Precise Nail Decollation Solution for Quality Control, Customization, Recycling or Testing.

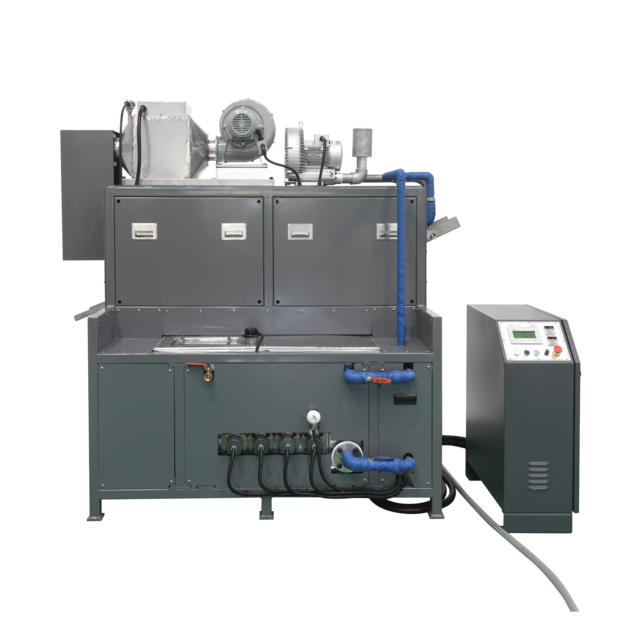

Nail demagnetizer for magnet conveyors

Programmable Welding for Industrial Wire Nail Production.

Double-capacity winding machine

High-capacity winding machine

Remove scraps from the wire during the production of nail tips.

Fast. Accurate. Seamless. – Autobander AB-40.

Revolutionized Performance – The Upgraded Fully Automatic Autobander.

Effectively eliminates dust and particles from the air in industrial settings, ensuring a safe and clean workspace.

Achieve superior dust collection with the robust 5HP Dust Collector, ensuring a clean and secure industrial workspace.

Advanced Auxiliary Equipment for Optimized Nail Production

In industrial nail production, auxiliary equipment plays a vital role in enhancing efficiency, reducing waste, and streamlining the overall manufacturing process. A well-designed auxiliary setup complements the performance of nail manufacturing machines, ensuring a smooth and cost-effective production line. Whether you need solutions for coil handling, welding, or nail separation, our range of equipment is tailored to meet the specific demands of industrial nail producers.

Hoppers: Streamlined Coil Handling

Optimize your coil handling process with advanced hoppers designed to integrate seamlessly with wire collating machines. These systems ensure smooth feeding of coils, reducing interruptions and enabling a continuous production flow. By minimizing manual intervention, hoppers not only save time but also improve the consistency and quality of the production line.

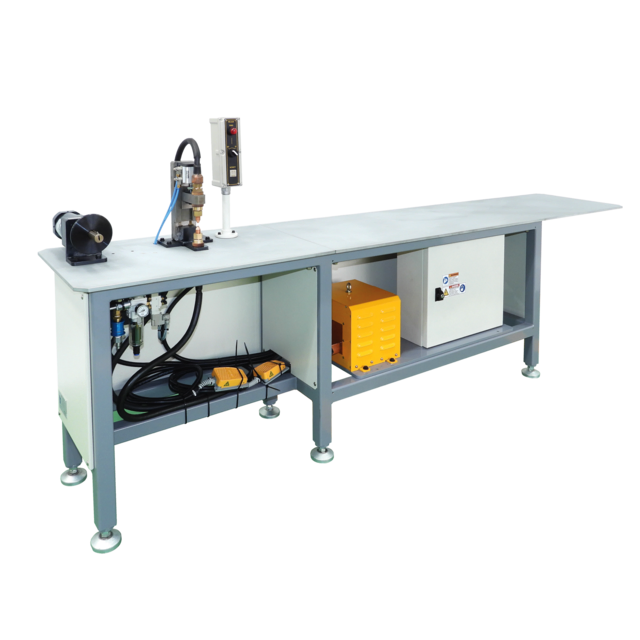

HF Welders: Superior Welding Precision

High-frequency welders deliver exceptional welding performance with programmable parameters and multi-channel capabilities. These versatile machines provide consistent, high-quality welding, ensuring reliable connections in the production of industrial nails. Their efficient design reduces downtime and contributes to the production of nails that meet the highest quality standards.

Rewelders: Sustainable Recycling Solutions

Rewelders offer a cost-effective and sustainable solution for handling defective coil nails. By recycling rejected nails, these systems reduce material waste and promote eco-friendly production. Rewelders are an essential addition for manufacturers aiming to maximize resource efficiency and minimize environmental impact.

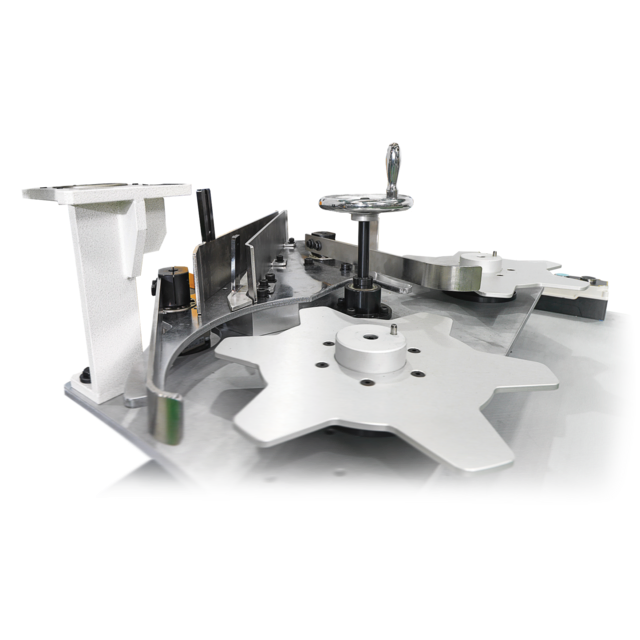

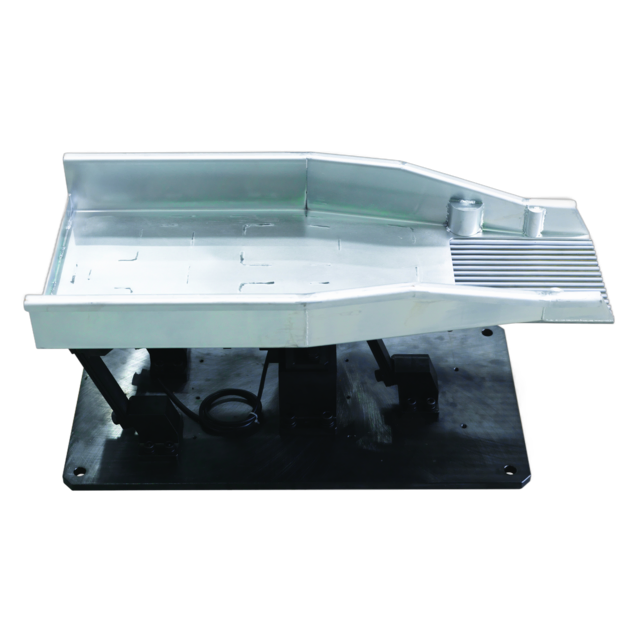

Nib Separators: Efficient Nail Handling

The nib separator, also known as a vibratory nib separator, features a magnetic conveyor and stainless-steel chute for seamless nail separation. This equipment ensures accurate and efficient nail handling, preventing blockages and maintaining the smooth operation of the production line.

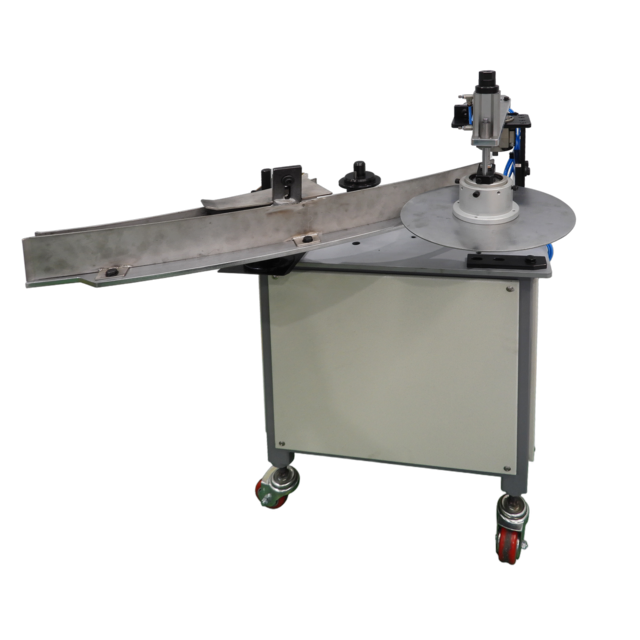

Auto Banders: Fast and Reliable Banding

Auto banders simplify the process of banding nails, achieving speeds of up to 5,000 pieces per minute. Utilizing common elastic rubber bands, these machines ensure stable performance and save time in end-of-line packaging. For high-volume nail manufacturers, auto banders are an invaluable tool for improving packaging efficiency.

Bowl Feeders

Bowl feeders are essential in nail manufacturing for efficiently orienting and feeding nails into production lines. We offers several models tailored to different production needs:

RF-32A: Features an 810 mm stainless steel bowl and Neo PWM vibrating system, ensuring precise nail delivery. It's designed for various nail sizes, enhancing production efficiency.

RF-36A: Accommodates nails with diameters from 2.1 to 4.1 mm and lengths between 30 to 300 mm. It achieves speeds up to 4,000 nails per minute, making it suitable for medium to large-scale production.

RF-40A: Equipped with a 1,020 mm bowl, it handles nail diameters of 2.1 to 4.6 mm and lengths from 45 to 300 mm. With a feeding speed of up to 4,000 nails per minute, it's ideal for high-speed production lines.

These models differ in bowl size, nail dimension compatibility, and feeding speed, allowing manufacturers to select the appropriate feeder based on specific production requirements.