Decollator – Precise Nail Decollation System for Quality Control

Decollator – Precise Nail Decollation System for Quality Control

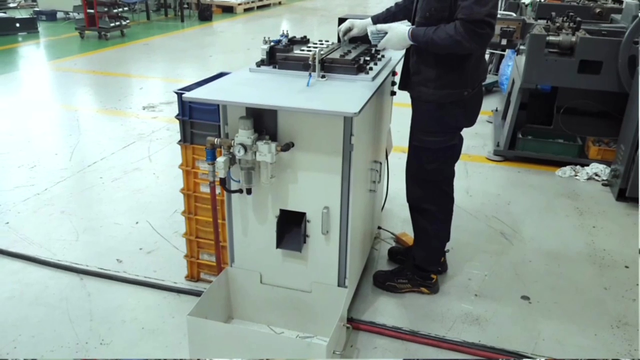

The Decollator is an essential tool for nail manufacturers looking to maintain the highest levels of product consistency and quality. Designed to efficiently separate mixed nails based on size, type, or defects, this system ensures that only nails meeting the required specifications proceed to the next stage of production.

Using advanced sorting technology, the Decollator identifies and removes incorrectly sized, rusted, or defective nails, preventing potential disruptions in the nail collating process. This enhances production efficiency and reduces material waste.

The machine’s robust automated system streamlines nail handling, providing manufacturers with an effective way to manage quality control while optimizing production line performance. Its integration into modern manufacturing lines improves sorting accuracy and helps prevent costly downtime caused by nail defects.

| Feature | DE-COLL |

|---|---|

| Code | 75_3000 |

| Weight | 500 |

| Depth | 600 |

| Height | 1 000 |

| Width | 1 250 |

| Electric Power | 2 kVA, 3P, 210 - 230 V, 50 - 60 Hz |

| Weight Kg Lbs | 500 kg / 1,100 lbs |

| Air Supply | 6 bar / 87 psi / (One 1/2" hose) |

| Space Required | 600 x 1 250 x 1 000 mm / 1' 11.6" x 4' 1.2" x 3' 3.4" |