Inspection Machine CQ-10s

CQ-10S Inspection Machine – AI-Powered Sorting for Industrial Nail Production

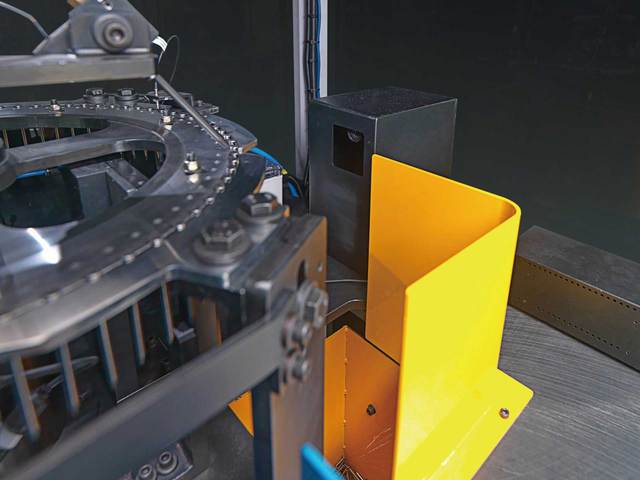

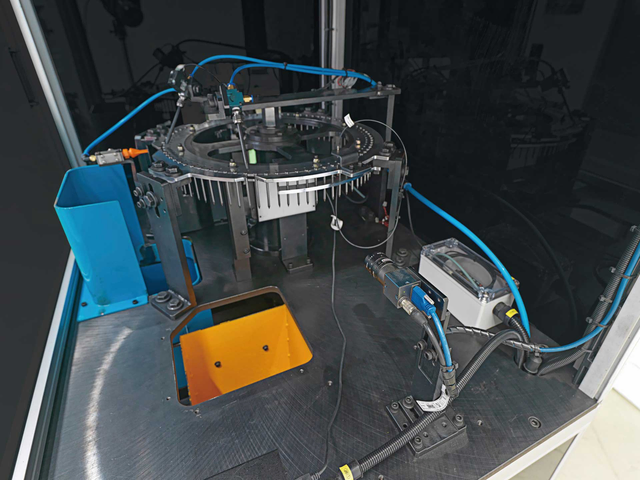

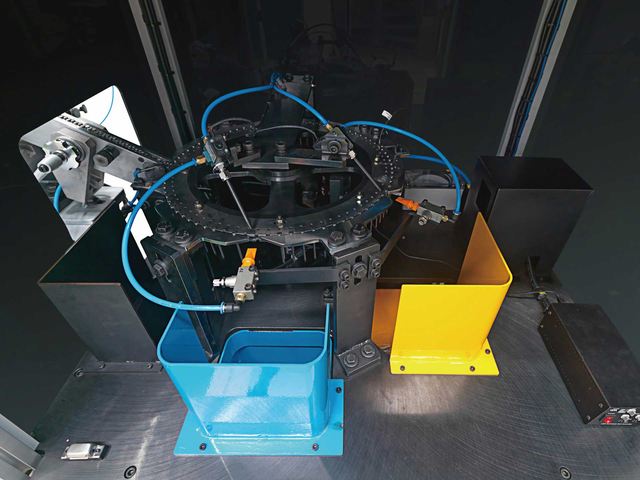

The CQ-10S Inspection Machine is an advanced AI-driven sorting system developed to enhance quality control in industrial nail manufacturing. This machine goes beyond standard inspection by efficiently sorting mixed nails based on length, shank type, head size, and other geometric features, ensuring uniform batches for further processing.

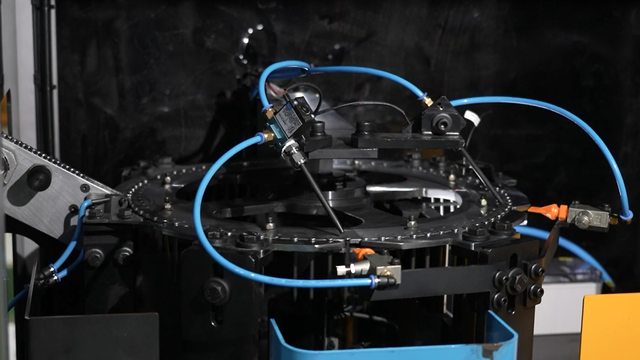

Utilizing high-speed vision technology, the CQ-10S precisely identifies and separates defective nails from production-ready ones, preventing inconsistencies that could disrupt nail collating machines. It efficiently detects issues such as incorrect dimensions, bent shanks, rust, or material inconsistencies, guaranteeing only high-quality nails are used in manufacturing.

Equipped with rotating index discs, the CQ-10S automates the sorting process, dramatically reducing labor-intensive manual separation and minimizing production downtime. This cutting-edge technology ensures maximum efficiency, reliability, and precision in modern nail production lines.

| Feature | CQ-10S |

|---|---|

| Code | 78-3000 |

| Weight | 2,200 kg |

| Nail Diameter Range | 2.1 - 3.05 mm (0.083 - 0.120 inch) / 3.1 - 4.5 mm (0.122 - 0.177 inch) |

| Nail Length Range | 45 - 100 mm (1 3/4 - 4 inch) |

| Speed | Up to 1,200 nails/min. |

| Electric Power | 2 kW max, 3P, 210-230 V, 50/60 Hz |

| Air Consumption | 350 liters/min. |

| Air Supply | 6 bar (87 psi), one 1/2 inch hose |