Inspection Machine CQ-10i

CQ-10 Inspection Machine – Advanced Quality Control for Nail Production

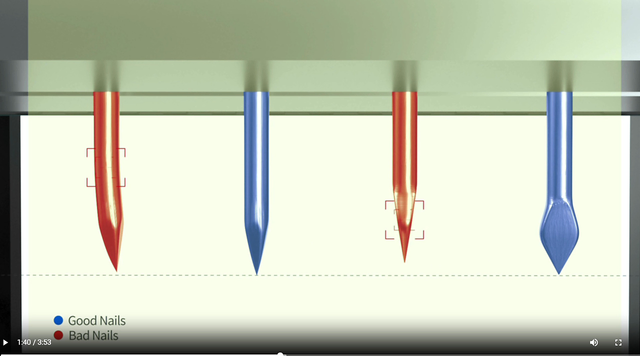

The CQ-10 Inspection Machine is a cutting-edge AI-powered quality control system designed to detect and eliminate defects in industrial nail manufacturing. Utilizing advanced vision technology, it rapidly inspects nails for dimensional accuracy, surface defects, and material integrity, ensuring that only high-quality products continue through the production line.

Equipped with a 360-degree rotation scanning system, the CQ-10 accurately measures critical nail attributes such as shank diameter, nail length, head roundness, tip sharpness, and surface irregularities, including corrosion or deformations. This intelligent system enhances efficiency by minimizing manual inspection, reducing human error, and increasing production output.

The CQ-10 also features an automated sorting mechanism that separates defective nails from high-quality ones, ensuring that only flawless nails reach further stages of processing. This level of automation helps manufacturers reduce waste, optimize production efficiency, and maintain consistent nail quality.

| Feature | CQ-10i |

|---|---|

| Code | 78-2000 |

| Weight | 2,000 kg |

| Nail Diameter Range | 2.5 - 3.77 mm (0.099 - 0.148 inch) |

| Nail Length Range | 50 - 100 mm (2 - 4 inch) |

| Speed | Up to 1,500 nails/min. |

| Electric Power | 3 kW max, 3P, 210-230 V, 50/60 Hz |

| Air Consumption | 300 liters/min. |

| Air Supply | 6 bar (87 psi), one 1/2 inch hose |