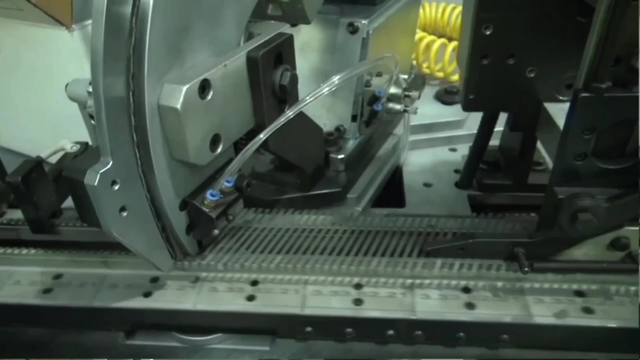

Plastic Strip Collator MS-5

MS-5 Plastic Strip Collator – High-Speed Precision for Nail Collation

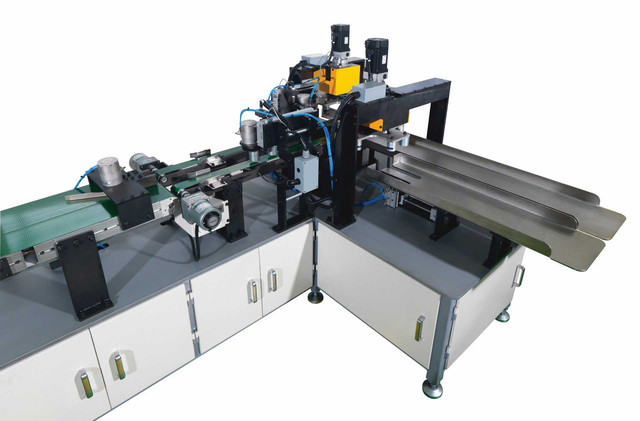

The MS-5 Plastic Strip Collator is an advanced high-speed collation system designed for efficient and precise nail manufacturing. This machine ensures a seamless collation process, creating strong and uniform plastic strip nails for industrial use.

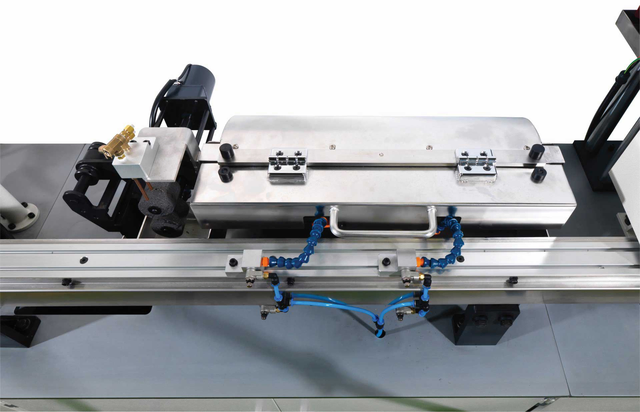

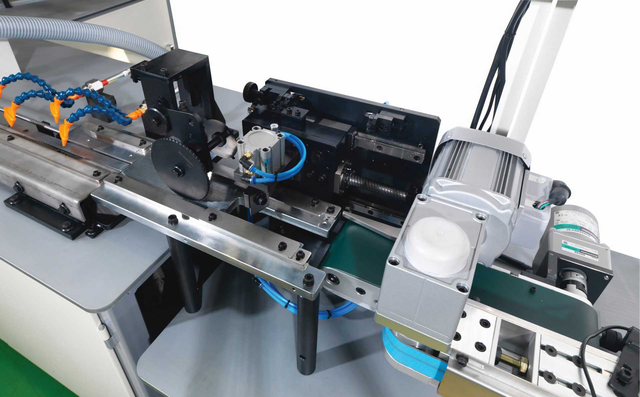

Built for high-volume production, the MS-5 provides consistent and accurate nail placement, ensuring that each nail is securely collated with plastic strips for smooth and reliable feeding in automated nailing systems. Its robust feeding and positioning mechanism minimizes errors and guarantees precision in nail alignment.

Equipped with an intuitive control system, the MS-5 allows for easy adjustments to nail specifications, making it suitable for a variety of nail sizes and types. The machine’s automated collation technology significantly reduces manual labor, improving efficiency and lowering production costs.

Designed for durability and long-lasting performance, the MS-5 operates with minimal maintenance requirements, ensuring uninterrupted workflow in plastic strip nail production. Its energy-efficient system and high-speed operation make it an excellent investment for manufacturers looking to enhance their nail collation processes.

| Feature | MS-5 |

|---|---|

| Code | 25-0000 |

| Weight | 4,000 kg |

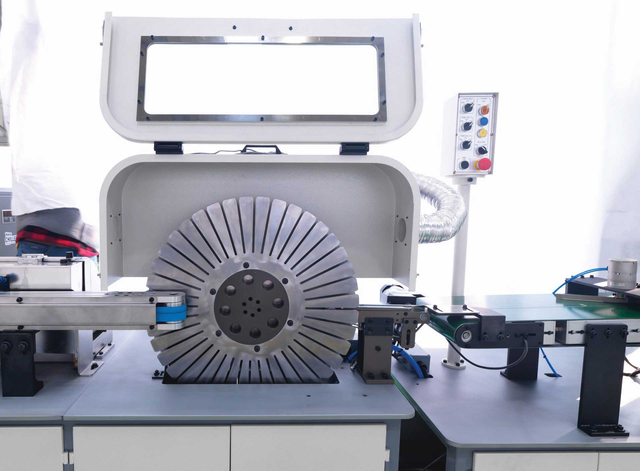

| Features | Dual collating brush wheels Dual extruder Resin dispenser Flying wheel cutter Dual forming wheels Coating, air cooling and drying Single lane autostacker Stable coating liquid supply Mirrored sets available |

| Nail Diameter Range | 2.5 - 3.77 mm (0.099 - 0.148 inch) |

| Nail Length Range | 45 - 100 mm (1 3/4 - 4 inch) |

| Speed | Up to 2,500 nails/min. |

| Electric Power | 35 kW max, 3P, 210-230 V, 50/60 Hz |

| Nail Angle Range | 19 - 23 degree |

| Nails Per Strip | 20 - 30 pcs |

| Air Consumption | 500 liters/min. |

| Air Supply | 6 bar (87 psi), two 1/2 inch hoses |