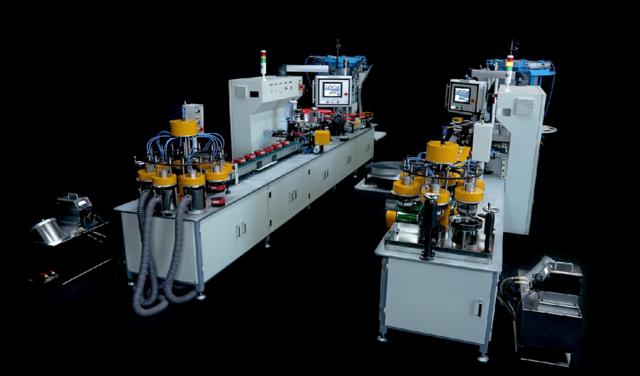

Plastic Strip Collator PCS-125

PCS-125 Plastic Strip Collator – High-Speed Precision for Nail Collation

The PCS-125 Plastic Strip Collator is a cutting-edge machine engineered for the automated collation of nails using plastic strips. This system is ideal for high-speed nail production, ensuring consistent alignment and firm attachment of nails to the plastic strips for seamless feeding in pneumatic nailers.

Built for high-volume manufacturing, the PCS-125 optimizes efficiency by significantly reducing labor dependency while maintaining superior collation precision. Its advanced feeding and positioning mechanisms ensure accurate nail alignment while minimizing material waste.

The PCS-125 features an intuitive control system that allows manufacturers to adjust parameters quickly, adapting to different nail sizes and strip configurations. This adaptability makes it a versatile choice for production facilities seeking to streamline operations and boost productivity.

Engineered for long-term durability, the PCS-125 requires minimal maintenance while delivering consistent and reliable performance. By automating the collation process, this machine enhances overall efficiency and contributes to a more cost-effective production workflow.

| Feature | PCS-125 |

|---|---|

| Code | 27-0000 |

| Weight | 3,200 kg |

| Features | Straight steep down rail: 1,600mm length, 30 degrees aligned. 31" (Ø800mm) Sheet loading magazine unit / sheet forming wheel unit. Nail inserting main wheel unit. Cutter: Count gear with sensor makes nail numbers per coil exact. Coating: Passing-by roller coating with recycling pump and stainless storage tank type. Servo driven coiler with tape applicator & magnet unloader. Stepping conveyor with warm air dryer |

| Nail Diameter Range | 2.1 - 3.77 mm (0.083 - 0.148 inch) |

| Nail Length Range | 16 - 125 mm (0.630 - 5 inch) |

| Speed | Up to 1,500 nails/min. / Screw Up to 1,000 pcs/min. |

| Electric Power | 10 kW max, 3P, 210-230 V, 50/60 Hz |

| Nail Angle Range | 0 - 16 degree |

| Nails Per Strip | 50 - 200 pcs |

| Air Consumption | 250 liters/min. |

| Air Supply | 6 bar (87 psi), one 1/2 inch hose |